Molten Galvanizing Product

SY-NT518 (Melting Galvanizing Flux Additive Wet Penetrating Agent)

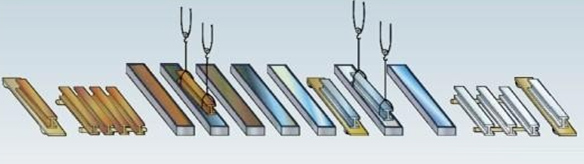

It's a wet penetrator. This is the order of the molten galvanized process.

Product Advantage

Warehousing → check → Degreasing → Water Washing → Picking →Water Washing → Fluxing +NT518 → Drying → Hot dip galvanizing →Water cooling → Inspection → shipment

◉ Flux Processing

It removes impurities on the iron surface, removes zinc oxides on the

skin plating water surface, and prevents the product surface from oxidizing.

The temperature takes about 80℃ to 5 minutes.

SY-NT518 Product Manual

Material Properties

| Product Type | Test Results | |

|---|---|---|

| Appearance | Yellow Translucent Award | |

| Creation | Special Cartion Activator Mixture | |

| pH (4%Aqueous Solution) | 7.0 ± 1.0 | |

| Ionicity | Cachion | |

| Specific gravity | 1.04 ± 0.05 | |

| Solubility | Transparent to a flux solution of 10 to 40 Be° | |

Main characteristics

- Increases fluid circulation in flux baths.

- Apply flux dries faster and the strength of the dried film increases.

- Increases the adhesion of plating, creating a strong sub-alloying layer.

- When the coating material is deposited in the zinc, the explosion ratio of the zinc is significantly reduced. (not more than 1M zinc acid under optimal conditions)

- Significantly reduce the Top Dross and Bottom Dross.

How to use

(Flux Per Capacity About 4%) :

→ Flux 10 Ton---Penetrant 400kg

→ Flux 20 Ton---Penetrant 800kg

→ Flux 30 Ton---Penetrant 1,200kg

→ Flux 40 Ton---Penetrant 1,600kg

* Supply

(Plating)

→ Month1,000Ton per 300~500kg additional

→ Month1,000Ton In production approximately 300~600kg

→ Month1,000Ton In production approximately 400~600kg

→ Month1,000Ton In production approximately 500~700kg

Provided, That at this time, the concentration of flux is maintained when supplementing water is injected due to consumption of liquid (Zinc Chloride ammonia)

- Conditions for Flux

→ Temperature : 65~75℃

→ Composition: Ratio of weight of zinc chloride and

ammonium chloride (approximately1:1.17)

→ Concentration : 15~40Be°

Precautions

- If the surface tension exceeds 35, there is a lack of penetrating agent content, so guarantee the proper amount.

- The amount of inflammation by desired concentration.

- This is the combined weight ratio of zinc chloride and ammonium chloride.

- This is the ratio of zinc chloride and ammonium chloride.

- Iron content increases as plating progresses. Please reduce the iron content by filtering.

Excessive iron content increases the effectiveness of the

dross and the penetrator decreases.

- The increase in chloride ions is associated with a decrease in pH

because it means the inflow of acid.

- When the ash is not easily removed from the cooling tank, sprinkle

ammonium chloride at a rate of approximately 120kg per ton of plating.

- There is a unique smell of its own, but the smell of the surfactant

itself does not have a significant impact on the human body.

Factors that reduce the effectiveness of scattering

- If excess acidic material enters the flux tank and the flux fluid is strongly oxidized, the structure of the surfactant may be damaged by acid.

- If unremoved oil is present in the flux tank, air bubbles may suddenly occur or oil combs may occur on the top of the flux tank, resulting in a sharp decrease in the uniformity of the fluid.

- It is recommended to prescribe separately if you particularly want a blanket due to the work process.

- The effect of scattering depends on the conditions of the atmospheric humidity, so high humidity is recommended for high flux temperatures.

- In some cases, the effect is not immediately shown even if an penetrating agent is added, but if it does not fall under (flux conditions), it slowly stabilizes and works as time goes by.

* Maintain surface tension at 30dyne/cm

- Add NT5181-3g/L to the Fluxtank.

- Flxu : ZnCl₂, NH₄ solution 사용.

- Add NT-518 in case of Zn bounce during melting plating.

* Use pH 4.0 to 6.0

- Maintain pH between 4.0 and 6.0 using ammonia water.

- If the pH reaches 2.0, we recommend a reconstruction bath.

* 1.0% Fe (keep below 10g/L)

- When Fe concentration exceeds 1.0%

Splashing may occur in the molten galvanized tank.